PRODUCT CENTER

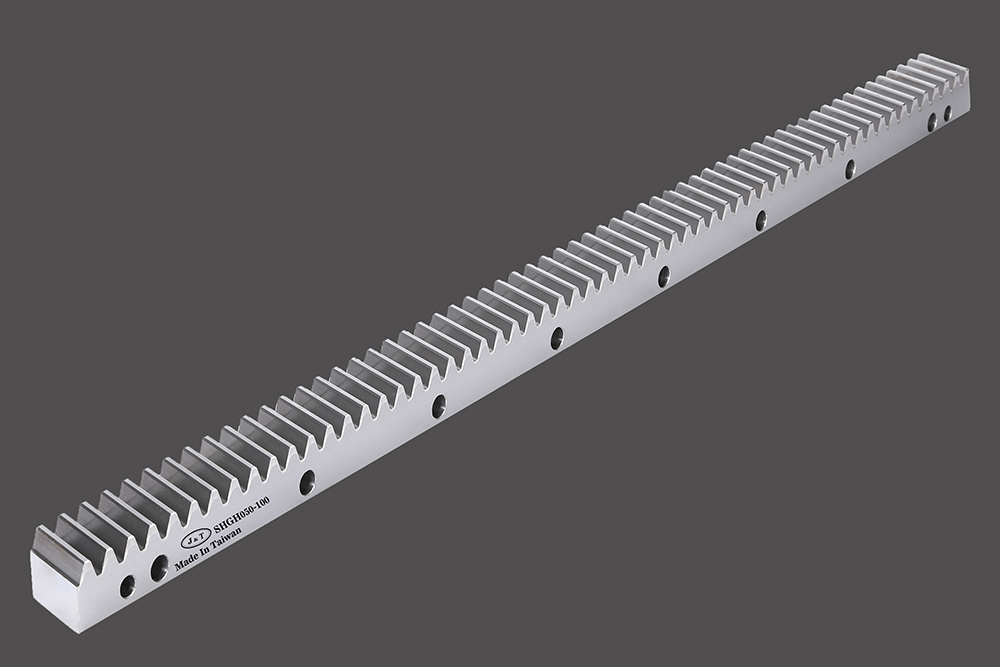

Grinding rack, high precision rack, guide rackProduct Center

Download

INDUSTRY APPLICATION

Strong competitiveness in the industry-

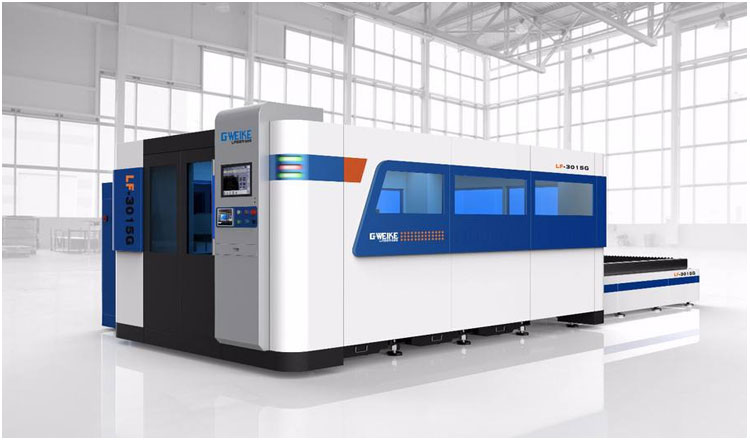

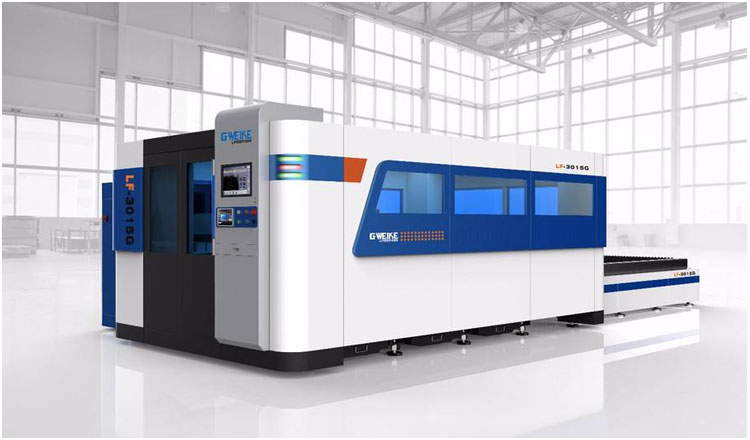

laser cutting

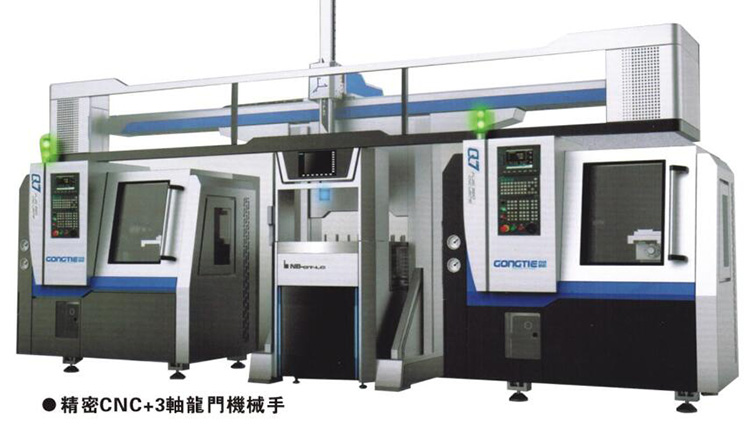

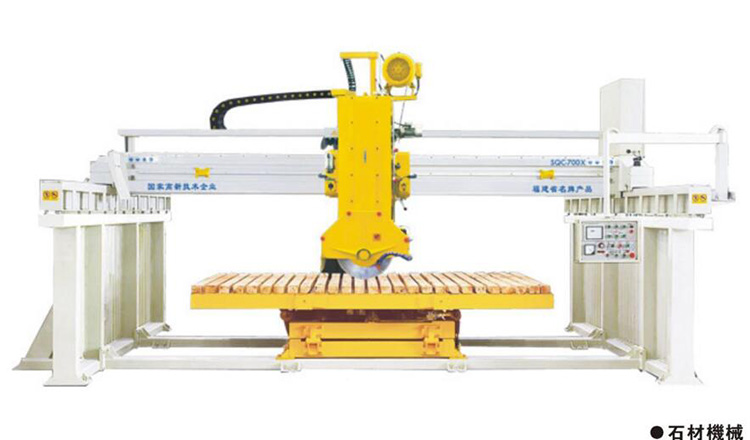

he quality, durability and precise discarding of precision rack can meet the international equal precision requirement. It is suitable for all transmission industry equipment, especially for industrial robotic manipulators, CNC machine tools, woodworking engraving machinery, CNC laser cutting machine, woodworking machinery automation equipment, stone cutting machinery, etc. It has become the industry. Excellent enterprises with strong competitiveness.

See Details -

-

-

-

-

Partner

INTERNATIONA STSNDARD

Consultation Hotline:13799879353

JINGTE

TransmissionHonesty, Quality First, Customer First

ABOUT US

Jingte Drive Technology Co., Ltd.

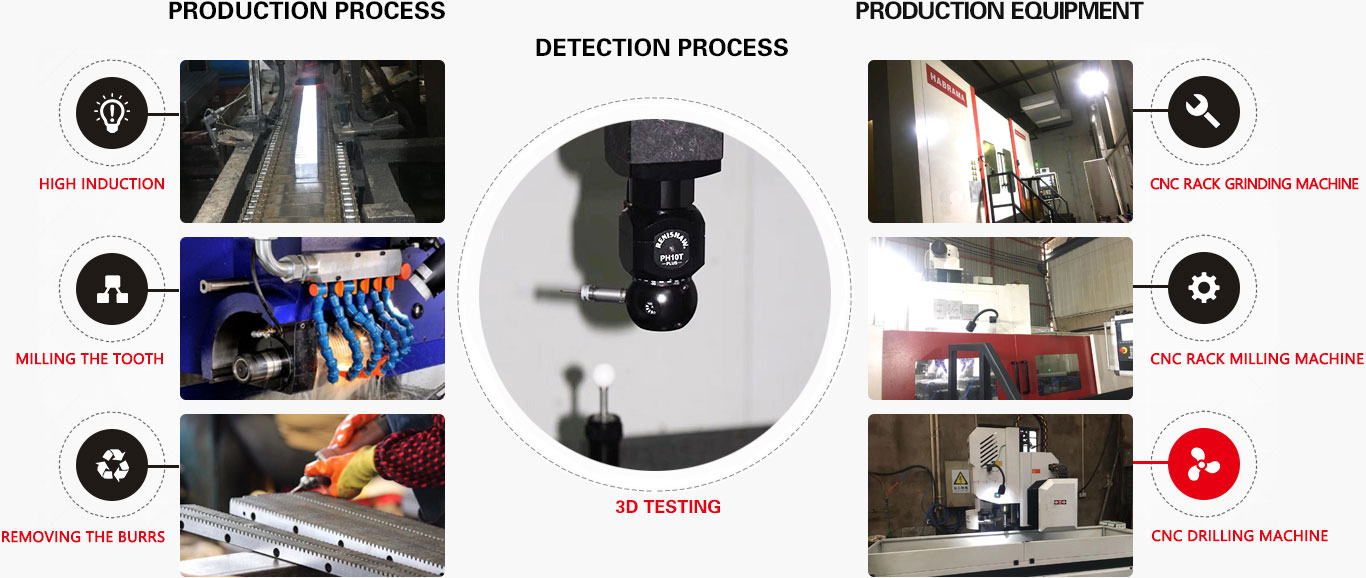

Jinjiang Jingte Drive Technology Co., Ltd. was established in Taiwan in 2008. In order to provide more comprehensive and fast service, Jinjiang Jingte Drive Technology Co., Ltd. was established in Fujian in 2015. It mainly engages in grinding rack, high precision rack, guide rack and so on. The company specializes in producing high-precision mechanical transmission components. With strong technical development team, perfect scientific management system and strong equipment, new processes are constantly developed in production, and world-class high-precision testing instruments are used to measure and test products, so that the products have stable quality assurance and timely delivery. The ability to solve current problems and problems can provide excellent products comparable to those of Atlanta, YYC, KHK, etc. The quality, durability and precise discarding of precision rack can meet the international equal precision requirement. It is suitable for all transmission industry equipment, especially for industrial robotic manipulators, CNC machine tools, woodworking engraving machinery, CNC laser cutting machine, woodworking machinery automation equipment, stone cutting machinery, etc. It has become the industry. Excellent enterprises with strong competitiveness. The company has more than 20 professional rack production equipment and rack accuracy grade up to GB10095-88 standard 7. In order to better adapt to market changes and meet high-end customers with high-precision rack demand, the company introduced CNC rack grinder from Germany in 2015. The rack precision produced by this equipment can reach (JIS II) DIN6n25. To meet the needs of high-end market. The company adheres to the business philosophy of "honesty, quality first, customer first" to serve the vast number of users. We sincerely welcome new and old friends from all walks of life, domestic and foreign businessmen to visit and patronize, to exchange experience extensively, to achieve mutual benefit and common development.

MoreNEWS

-

-

Main Application Range of Rack

The use of racks is very extensive, todays small circular rack for you to introduce the main application of racks, lets take a look at it. Rack is suitable for fast and accurate positioning mechanism.(1) Racks are suitable for CNC tools, milling machines, drilling machines, lathes, machining centers,…

[2019-09-04] -

Rack knowledges

Rack, in production and life with the use of gears, the two are inseparable. The tooth profile of the rack is a straight line rather than an involute (plane for the tooth surface), which corresponds to an infinite cylindrical gear with indexing circle radius. Here are a few rack tips to give you a cl…

[2019-09-04] -

Rack Manufacturers Analyse the Advantages of Precision Rack Processing with Different Rack Processing Methods

At present, how many people know about the knowledge of rack? Today, lets drop this and the problems of professional rack processing and rack manufacturers. Rack processing manufacturers take you to see "the advantages of different rack processing methods for precision rack processing", hoping to he…

[2019-09-04] -

Modulation and High Frequency Quenching of Rack

For mechanical parts, such as shaft parts, transmission parts, before or after processing, some processing is needed to adjust the internal structure, so in many cases, various processing has become an indispensable method for these parts. The modulation treatment and high frequency quenching of rack…

[2019-09-04] -

What will happen to the rack after heat treatment?

After the rack is processed, the rack will be heat treated. How will the rack change after heat treatment? First of all, the rack after heat treatment usually undergoes some deformation. According to the different heat treatment methods, materials and technical requirements, the deformation is about…

[2019-09-04] -

What are the methods of rack processing?

The rack is divided into helical rack and straight rack. They are used in conjunction with helical cylindrical gear and straight cylindrical gear respectively. The racks tooth profile is a straight line rather than an involute, which is equivalent to an infinite cylindrical gear. There are many kinds…

[2019-09-04]

-

-